In general, shims are used to hold heavy objects in place until they are permanently attached with bolts, welding, grout, adhesive, or another method. Shims are commonly used throughout various construction work for accurate leveling and alignment. The list of common shimming uses below is not exhaustive but serves to demonstrate the versatility of shims.

In general, shims are used to hold heavy objects in place until they are permanently attached with bolts, welding, grout, adhesive, or another method. Shims are commonly used throughout various construction work for accurate leveling and alignment. The list of common shimming uses below is not exhaustive but serves to demonstrate the versatility of shims.

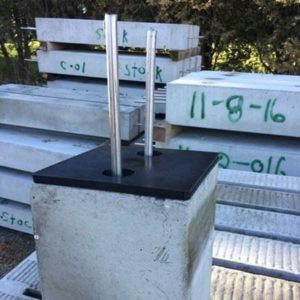

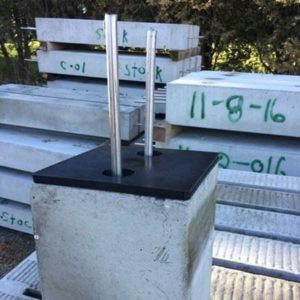

Division 03: Precast and Tilt-up Applications

- Tilt-up Concrete: Leveling construction shims align panels in preparation for final attachment.

- Precast Concrete Panels: Shims align panels vertically and horizontally to maintain joint spacings before final attachment.

Discover more about the usage of plastic precast and tilt-up shims as construction leveling solutions.

Division 04: Masonry

- Stone Masonry: Shims allow for both temporary and permanent joint spacing.

- Stone Panel Cladding: Plastic shims can align panels vertically or horizontally to relieve stress while mortar sets.

- Terra Cotta: Brittle materials can be temporarily cushioned with shims before being fixed or sealed into place.

Discover more about the usage of plastic masonry shims.

Division 05: Metal

Typically, structural steel is shimmed with steel shims. However, many other metal objects are shimmed temporarily with plastic shims before welding, grouting, or bolting into place.

Color-coded shims can also separate dissimilar metals or provide a thermal break as plastic leveling construction shims are available in fire-rated materials.

Division 06: Wood

Heavy wood that would crush a wood shim can be shimmed with plastic shims. Typical applications include heavy timber framing, glu-lam members, and prefabricated joists or trusses.

Read this Different Shim Material article to determine if plastic shims are more useful in your application compared to metal or wood shims.

Division 07: Walls and Roofs

- Wall and Roof Panels: Shims are used for aligning panels, girts, and purlins.

Division 08: Windows and Doors

- Doors and Frames: Plastic shims align frames while fastening in place.

- Entrance, Storefront, and Curtain Wall Systems: Solid shims can align members or panels, vertically or horizontally, as well as separate glass panels permanently or temporarily.

- Blast-Resistant Doors and Windows: Extra resilience of permanent shims may be required for optimal blast-resistance.

- Skylights and Sloped Glazing Systems: Shims provide leveling and alignment.

- Louver Systems: Shims provide leveling and alignment.

Discover more about the use of construction leveling solutions like plastic window and door shims.

Division 09: Restoration

- Stone Flooring: Shims provide temporary spacing and can align panels for Interior Stone Cladding.

Discover how plastic restoration shims are particularly useful for re-leveling floors, foundations, and concrete bearing surfaces.

Division 10: Directories, Partitions, and More

- Heavy Objects (Directories, Signage, and Telephone Kiosks): Shims can align temporarily to ensure proper setup before being permanently fixed into place.

- Folding, Sliding, or Coiling Partition Tracks: Tracks can be shimmed for alignment for a smoother operation of the partitions.

Shims can also be utilized for heavy-duty tubs and shower doors, storage specialties, and flagpoles.

Division 11: Heavy Objects and Equipment

Heavy objects, such as parking equipment and loading dock equipment, can be aligned with plastic shims temporarily before being permanently fixed into place.

Division 12: Seating

Heavy objects including metal benches, bleachers, and fixed audience seating can be aligned temporarily with solid leveling construction shims before being permanently fixed into place.

Division 13: Structures and Enclosures

- Amusement Park Structures and Equipment: Shims provide leveling and alignment and some shim styles fit around bolts and anchors.

- Kennel Enclosures and Gates: Shims can provide alignment so all enclosures and gates match up correctly for proper closure.

Division 14: Passenger Conveyors

- Elevators, Escalators, Moving Walks, and Lifts: Color-coded shims align rails and equipment.

Division 23: Heating and Cooling

- HVAC Equipment: Can be aligned using shims before being permanently fixed into place.

Shim Applications and Uses

Utilizing solid plastic shims allows easily leveling, alignment, or positioning of objects. Since shims can be used in a variety of industries and for multiple purposes, Grove Shims™ manufactures a wide range of shim styles and sizes designed to meet the needs of your industry and project, including custom shims.

In general, shims are used to hold heavy objects in place until they are permanently attached with bolts, welding, grout, adhesive, or another method. Shims are commonly used throughout various construction work for accurate leveling and alignment. The list of common shimming uses below is not exhaustive but serves to demonstrate the versatility of shims.

In general, shims are used to hold heavy objects in place until they are permanently attached with bolts, welding, grout, adhesive, or another method. Shims are commonly used throughout various construction work for accurate leveling and alignment. The list of common shimming uses below is not exhaustive but serves to demonstrate the versatility of shims.